Manufacturers set quality and performance standards for their products. Product testing is an essential step in ensuring quality and meeting customer expectations. Product testing also ensures products meet specific technical requirements. Testing involves putting products through experiments and evaluating their performance under varying circumstances.

As an original equipment manufacturer (OEM) for doors and windows, you need reliable hardware that can live up to your standards. Rockwell Security is proud to be an industry leader in manufacturing door and window hardware. With more than 30 years of experience in the industry, we recognize the importance of product testing. Explore the top five reasons why product testing is crucial to OEMs to help you make decisions regarding your products.

1. Promote Quality Assurance

Products must meet specific safety and quality requirements before going on the market. Quality assurance (QA) testing allows manufacturers to objectively verify the product’s quality. Then, they can deliver a product that meets manufacturing standards and functions as it should. Consider a few benefits of QA testing:

- Meeting technical requirements: Some product requirements come from an outside organization. Independent and government organizations work to ensure product quality and protect consumers. One example is the American National Standards Institute (ANSI). OEMs may also have internal quality standards for their products. Products must pass these requirements before the OEM can manufacture and distribute them.

- Maintaining the company’s brand: Companies of all kinds have reputations. Cultivating a unique brand improves a business’s sales and helps it attract more customers. Quality assurance testing is essential for maintaining a brand’s reputation. The extra step of quality assurance testing ensures companies distribute consistent products. It also justifies the claims they advertise. Customers develop positive opinions of brands when their products perform well.

- Verifying product functionality: Product testing also makes sure products function correctly. Manufacturers design products to perform a certain way, and problems with functionality could indicate design flaws. A product that fails a QA test may need modifications.

OEMs benefit from ensuring their products meet quality standards. Doors and windows are designed to open and close smoothly at specific points. Manufacturers must verify that latches, doorknobs, locks and other hardware perform as intended. Quality assurance testing confirms that locks fasten and doorknobs turn as designed.

For example, door pulls are an alternative to doorknobs in areas of high traffic. This type of door hardware must allow adequate hand room so users have the proper grip on the pull. Door pulls must also be made out of a sturdy enough material to pull the door. Quality assurance testing for door pulls verifies the design and construction of the hardware and ensures the door pulls are compatible with the intended use.

2. Discover Your Product’s Endurance

Different products must endure varying levels of stress. Product endurance depends on the functions the manufacturer designed it to fulfill. Some products must survive hard wear and tear, while others are intended for gentler use.

OEMs want their products to perform the job the customer expects them to perform. If the product doesn’t function as intended, customers will be displeased. Product testing is an effective strategy for measuring a product’s durability and seeing how long it’ll last.

Testing a product’s endurance involves performing various kinds of exercises. These tests purposefully subject the product to everyday stresses it might encounter. The testing team then observes the effects of the stress and how quickly the product experiences wear. The team determines whether the product needs more improvements to increase its endurance. The engineers may need to return to design and solve the issue if the product displays weak endurance.

Homeowners and businesses expect their doors and windows to stand up to some routine wear. Doors and windows are essential building components that should last several years. The materials, hardware and overall design of these products impact how well they can withstand various strains.

Door and window OEMs must test their products to meet everyday stresses like:

- Rain: Most areas experience varying levels of rain from time to time. Doors and windows must last years under the stress of regular rain storms. Paint, finishes and window panes should withstand precipitation and moisture.

- High humidity: Some areas also experience high humidity, especially in the summer. Doors and windows should be able to withstand certain levels of humidity without warping prematurely.

- Extreme heat and cold: Severe temperatures can impact doors and windows. The changes in temperatures throughout the year can cause lower-quality wood to shrink. Various brands of windows and doors must also meet insulation standards for weather protection.

- Aging: Some testing measures the effects of aging to determine how long the product will last. This test tells manufacturers what kind of warranty they can give their products.

3. Catch Product Defects Early

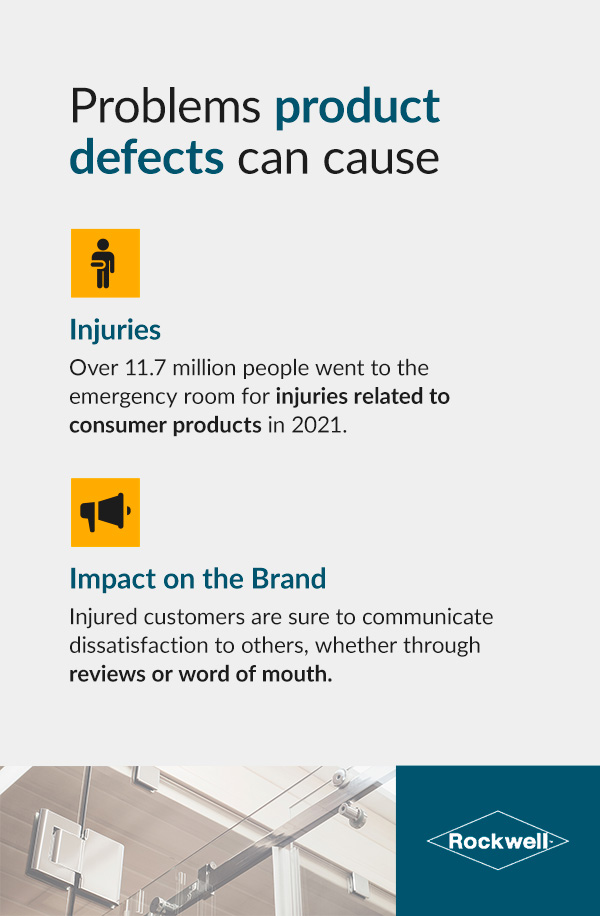

Product defects are issues with a product’s construction. These problems can cause severe issues for consumers and manufacturers, including:

Injuries

Defective products can cause injuries ranging in seriousness. Injuries could occur for several reasons, including defects in the product’s design or manufacturing process. No customer wants to experience bodily harm because of a product defect. If a defective product injures a consumer, they could sue the manufacturer over negligent product testing. A court could then hold the manufacturer liable for any medical and legal costs resulting from the injury or death.

These product issues are relatively common. The United States Consumer Product Safety Commission (CPSC) investigates product safety information. The CPSC then creates regulations to protect the public from serious risks. According to research from the CPSC’s National Electronic Injury Surveillance System, over 11.7 million people went to the emergency room for injuries related to consumer products in 2021. If they were using the product as the manufacturer intended and it still injured them, they may have a legal right to sue the manufacturer.

Manufacturers also want to avoid producing defective and harmful products. Product testing is one step in the process of catching defects early on. Testing allows door and window manufacturers to save the money, time and other resources involved in a lawsuit. By protecting customers, manufacturers also demonstrate that they care about producing functional and safe products.

Impact on the Brand

Product defects also impact a brand’s reputation and may decrease sales. Injured customers are sure to communicate dissatisfaction to others, whether through reviews or word of mouth. The media can also spread the news of customer injuries from defective products.

OEMs can experience several benefits by preventing defective products from leaving their facilities. Manufacturers can increase sales, avoid product recalls and protect their brand’s reputation. These benefits demonstrate that eliminating product defects is vital.

Door and window panes, hardware and other components can potentially cause consumer injuries. If these products are designed or produced incorrectly, they can also cause damage to other elements in the building. Consider a few common window and door defects that can potentially cause injuries or negatively impact a brand:

- Improperly installed door handles and hardware

- Structurally unsound or faulty window latches

- Window panes leaking at corners due to improper sealing

- Low-quality paint that chips and wears quickly

- Damaged window glazing and broken seals

- Poor timber preparation that leads to rot

4. Meet Customer Expectations

Your customers choose your products because they have certain expectations. A product’s design, performance and aesthetic could influence a customer’s purchase. These expectations come from various interactions with the product through a previous purchase or advertising. Customers can also develop expectations by communicating with other customers.

Meeting expectations based on your advertising messaging is essential. If OEMs make claims about what their products do or how they look, they should follow up on those claims. Meeting customer expectations by providing high-quality products provides several benefits. By meeting expectations, your can increase brand loyalty, boost sales and stand out from your competitors:

- Improve brand loyalty: Satisfying your customers can strengthen your customer base. Customers are more likely to purchase other products from you again when they’re pleased. This loyalty to your brand can strengthen your business in the long term.

- Increase sales: Pleased customers tell others about their experiences. Your customers may write positive reviews or talk about your products to their friends and families. Meeting expectations can translate into increased sales in the future.

- Rise above competitors: Satisfied customers often recommend products to others. By meeting customer expectations, you give them something positive to communicate to others. Word-of-mouth advertising can help you find your target market and stand out from competitors.

For example, suppose an OEM claims their windows are durable and insulate well against the cold. Testing the windows can provide concrete numbers to substantiate these claims. When a manufacturer offers confirmation to support its messaging, it communicates trustworthiness. Customers who buy these products and see the quality for themselves will be satisfied with their purchases.

At Rockwell Security, we work to ensure the highest quality for our products by performing product testing and using top-grade materials. Our industry experience also allows us to provide impeccable service to our clients. These qualities enable us to make claims about the craftsmanship and design of our products and our customer service.

For example, our deadbolts have been tested to meet stringent ANSI Grade 2 standards. This measurement determines product strength, security and durability. In addition, our manufacturing facility is ISO9000-certified. This quality management system provides guidelines to help organizations improve product quality.

5. See if Your Target Market Will Buy It

Product testing is essential for determining whether products are durable and function appropriately. This step in the manufacturing process is also beneficial for gauging public interest in a product.

Product testing helps OEMs determine whether they can expect interest in the product from their target market. Completing this process can save OEMs time and money on product development and advertising. Having the focus group test a product can also reveal their interest before the product launch.

Many new products fail every year. Product launches may fail to generate enough awareness, and products may have defects that decrease sales. Part of the reason why products fail is that there wasn’t a market for the item in the first place. With help from a focus group, OEMs can perfect their products and gauge audience interest. Focus groups can show OEMs whether the product is worth manufacturing in its current state.

Product testing through a focus group can give OEMs valuable insight. This process demonstrates the product’s ability to meet the target market’s needs. Focus group testing involves providing a small group with a range of product options and asking for their initial reactions to each one. Manufacturers often ask them about a series of essential product metrics.

This strategy helps OEMs gather the audience’s feelings about topics like:

- The product’s design

- The product’s effectiveness

- The customer’s purchase intent

- The quality of materials

- The value of the product

- The product’s uniqueness

Window and door OEMs can gain several benefits from using focus group testing. A few advantages of testing a door or window through a focus group include:

- Determining whether product development is still needed: If the audience generally likes the product, only a few elements may require testing. Perhaps the door construction is excellent, but the hardware needs improving.

- Gauging interest in specific product features: The focus group may appreciate certain features the manufacturer didn’t expect to be as appealing. Specific comments might also demonstrate an interest in a feature the product doesn’t have. Manufacturers can use this information to test the value of certain elements.

- Solving design flaws: The focus group should address any design issues the manufacturer may have missed. These could include door hardware that doesn’t work correctly or window panels that stick.

- Introducing customers to the product: Focus group testing also helps increase customer awareness. This strategy can help OEMs get a head start on advertising before the product launch.

- Ensuring research and development yield the best results: Testing products with a focus group can improve the research and design process for the following product. Perhaps the focus group points out a flaw in the development process. OEMs can use this information to enhance their approach.

Choose Rockwell Security for Your Door and Window Hardware Needs

Customers want reliable, durable products that can stand the test of time. Testing your products can help ensure you’re delivering quality doors and windows to market that your customers will find valuable and worth the investment.

Designing high-quality, elegant and sturdy doors and windows is easier when you partner with Rockwell Security. For over 30 years, we’ve been providing OEMs, engineers and purchasing agents with durable, innovative door and window hardware. We use top-quality materials like aluminum and solid brass in our expert craftsmanship to deliver stunning hardware solutions.

Browse our selection of commercial and residential door and window hardware today!

Trackbacks & Pingbacks

[…] Testing products for safety brings big benefits to both buyers and makers. It helps keep customers safe and boosts a company’s image. It also saves money over time11. […]

Comments are closed.